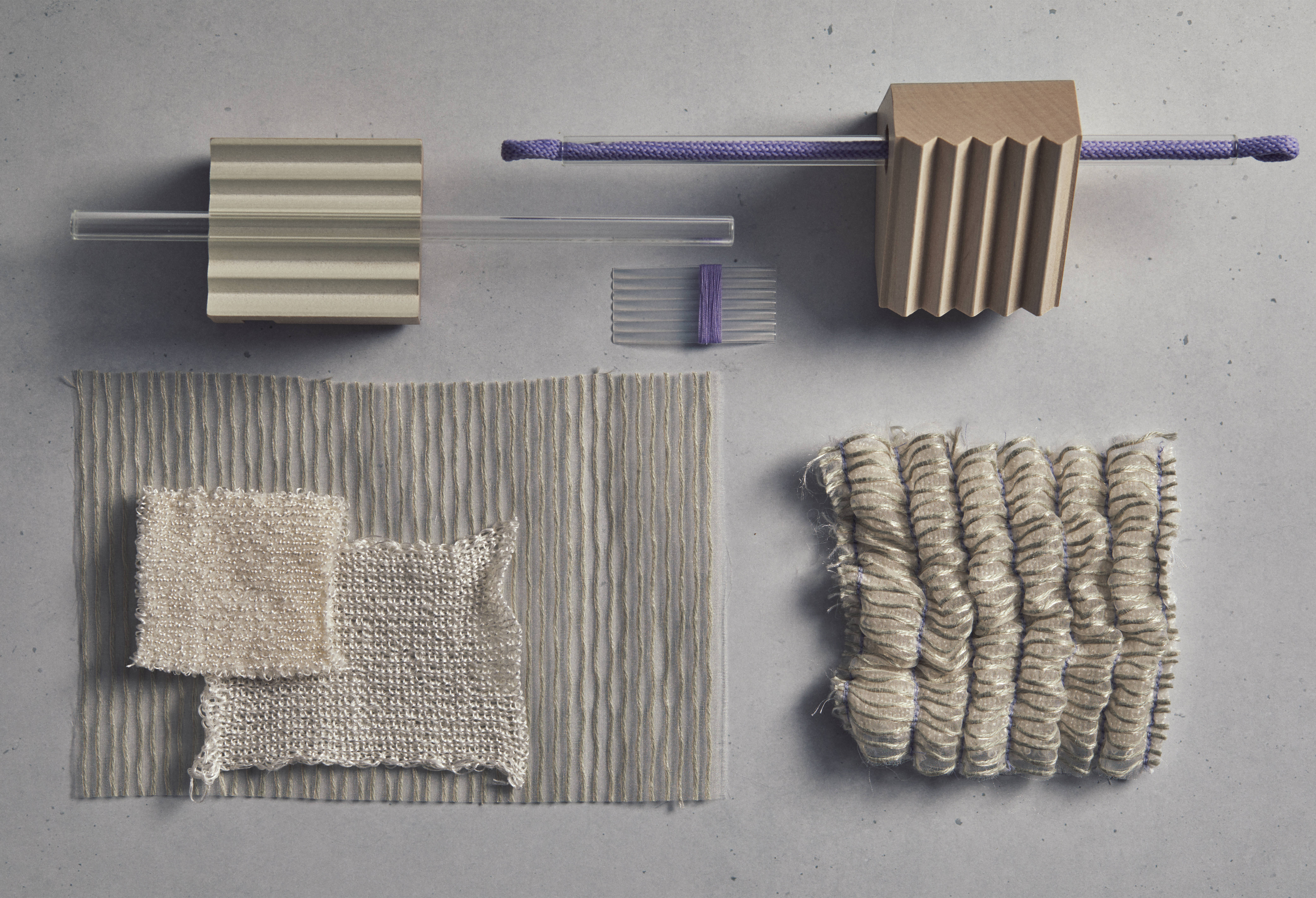

»Layers of Value is an example of sophisticated upcycling at a textile design level using a systematic finishing method. Textile waste and deadstock are given a REMAKE using a series of techniques involving layering. This approach is reproducible at scale and also offers a wide range of variety thanks to the ever-changing feedstock.«

Prof. Friederike von Wedel-Parlow

Three questions for Virginia Reil

How did the idea for Layers of Value come about?

Pre-consumer waste, surplus production and the resulting deadstock are keeping industry on its toes. Because so many blended materials are used, there’s a dearth of ideas and solutions for recycling or upcycling in the home textiles sector. As fibre blends are hard or impossible to separate, incinerating them is usually the last step. At the moment, warehouses are full and valuable materials and resources are being wasted while new items are produced. As a designer, it was important to me to examine this problem in more detail.

What was your personal highlight in the Layers of Value development process? Was there a low point?

Actually, there were quite a few. During the process, I depended on collaborations with industry. Machine utilisation (MALIMO) was the biggest problem. It was impossible to integrate prototypes into industrial processes. At the research institute, they replaced a machine and the new one was way too unstable. I changed the technology and developed a concept on the ZSK embroidery machine. That was the best thing that could have happened. Embroidery technology was much more suitable and offered more creative opportunities.

Where do you see your project in the next five years?

Scaling the prototypes would be the next step. The remake potential is enormous. I can well imagine one-offs and limited editions for interiors. Modular solutions on walls or furniture would be objectives that we could well pursue in five years. I can envisage applications in art on buildings, in architecture, and the accessories sector. I hope that companies will recognise this potential and give designers more opportunities to look at existing material and see my modular system as an incentive.